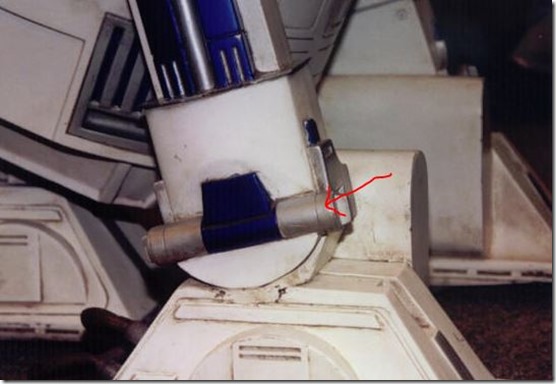

The next part is the ankle cylinders. There are four of these in total, two on the inner leg and one on the outside of each of the outer legs. They are basically the same except that the cut out on the back of the cylinder is a different size for the center leg then the outside legs.

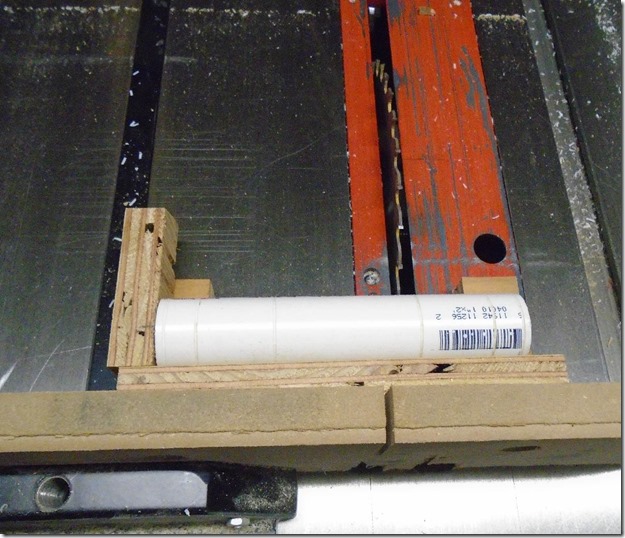

I made the cylinder out of a piece of PVC pipe which was the perfect size for them. I started by cutting the pipe to the correct final length. The next step was to cut the groove that g around the cylinder. There are six of these grooves, two right near the ends, two a little further in, and two right by the blue part. To make these cuts I used a mini table saw with an abrasive blade that can make a fine enough cut. I clamped one block across the bed of the saw to roll the pipe against, and second block to establish the position of the groove.

I placed the pipe against the two stops and then rotated it to make the cut. I moved the end block to make each of the cuts.

The next step was to cut out the back of each cylinder so that it can fit around the ankle. I made these cuts on my full sized table saw using a special jig to hold the cylinder. A block on the side and back of the jig hold the pipe in position. I drilled a hole through the end of the pipe so I could screw it to the jig to prevent it from rotating while I made the cut.

I adjusted the saw blade to make the correct depth cut which is about half way through the pipe. I then placed this again my miter gauge and made multiple cuts along the length of the pipe.

You can take the time to make enough cuts to totally remove the material. I made fewer cuts, broke out the pieces and the cleaned up the edges with a file.

Here is the part with the cuts complete and edged cleaned up. I eventually filled in the hold with some hobby putty.

Lucky! I just had to mark and cut out with a hand saw and a Stanley knife lol.

ReplyDelete