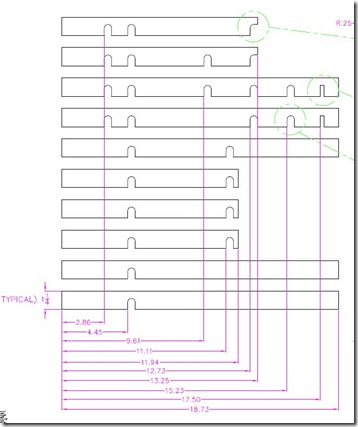

In my last post I talked about using a router to do pattern cutting, so the next step is to make the template of the leg. I started with this drawing which includes both the leg and the ankle:

There are a couple things to note about this drawing. Above the ankle is a feature called the ankle bracelet. This is a separate piece which is added later so you need to make the pattern so the side of the leg goes all the way down to the ankle. I have circled this in blue below. The red circle shows a notch in the leg which is also something that will be added later.

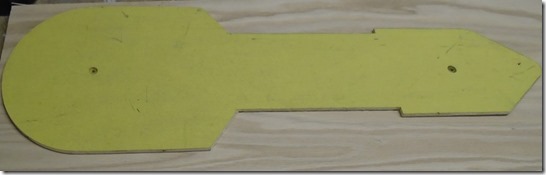

I printed out the template full size and used it to trace the pattern onto a piece of lauan plywood, but you could also glue the template down like I did for the frame components. With the pattern transferred to the plywood I need to find accurate ways of cutting it out. For the long cuts I used a circular saw and a guide fence. I have a small, battery powered circular saw which is perfect for making these sorts of cuts.

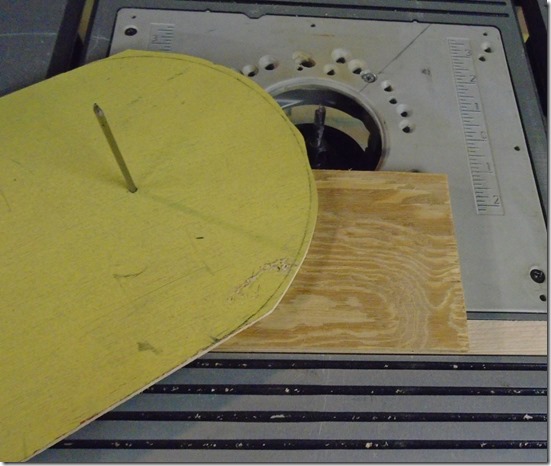

For the curve of the shoulder I did a rough cut on the band saw and then finished it using the router table jig that I have used for the frame cuts.

The angle on the ankle were just on a miter saw, and the rest of the cuts were finished on a band saw. Finally I cleaned up the rounded end of the angle on a drum sander.