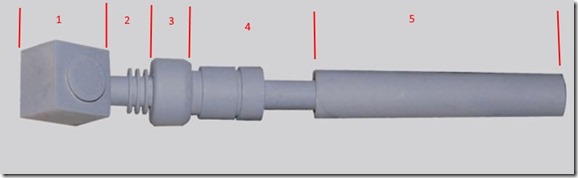

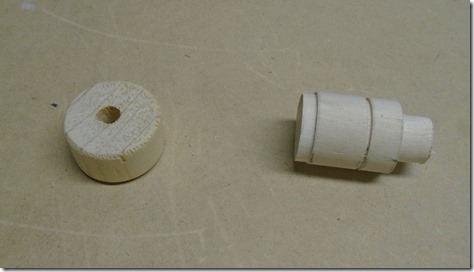

Here is a look at how I mounted the legs to the frame., Each leg has a piece of threaded iron pipe screwed into the shoulder flange. I used a piece of pre-threaded pipe and just cut it in half.

The two smaller pipes attached to the legs then go into a larger piece of pipe.

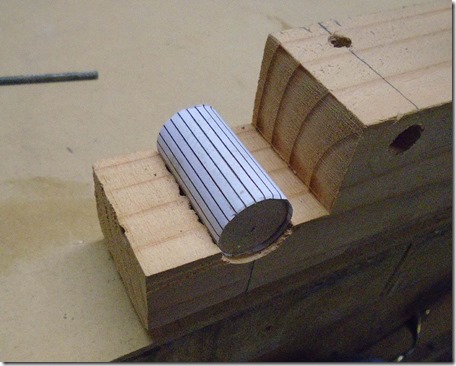

To hold that larger pipe in place I added blocks on the inside of the frame. I also wrapped some tape around the pipe to keep it centered and not slide out.

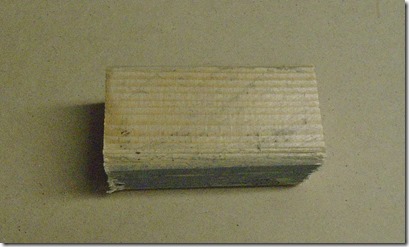

To make the blocks I started with a square piece of plywood and then drilled a hole the same size as the pipe.

I then cut out one side of each piece on the band saw to provide a way to get the pipe in. In hindsight I realized I only really need to to this on side, there was enough room to get the pipe in on one side without the cut out.

I glued the main piece onto the frame and the screwed the smaller piece into place when the pipe was installed. To keep the legs in the correct orientation I drilled a hole through the frame and into the shoulder hub and then inserted a pin to hold the leg at the correct angle.