The next piece I needed for the shoulder was the shoulder hydraulic.

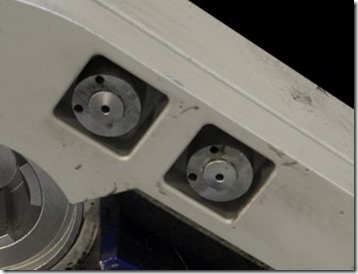

I made this is three parts, the round central shaft and the two blocks at either end that hold it to the shoulder. To make the shaft I turned to a pretty specialized piece of equipment. This is a Unimat mini machine lathe. I rescued this one from my father’s basement where it had been water damaged. It took a lot of WD-40, rust remover and scrubbing to get it taken apart and cleaned up. I also got replacement belts from Toms Tool Store. With this tool I could have made the shaft from metal, but I am more comfortable with wood so that is what I went with.

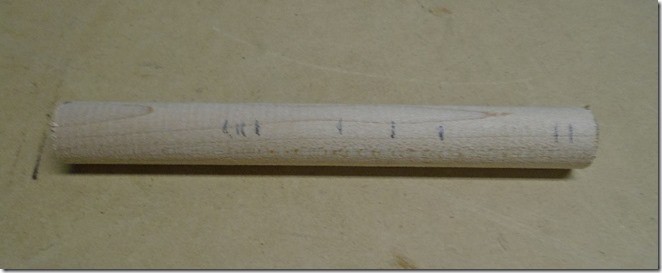

I started with a dowel that matched the largest diameter of the finished part. Using the measurements of the plans I marked the location of each section that needed to be cut. Once the piece was mounted in the lathe I spun the dowel and marked the lines all the way around.

Next I used a couple different cutting bits to cut each section. I use a pair of calipers to check when the correct diameter had been reached.

Here is the piece after the lathe cuts had been made. For now I did not cut off the ends because I needed to put it back in the lathe later for one more cut.

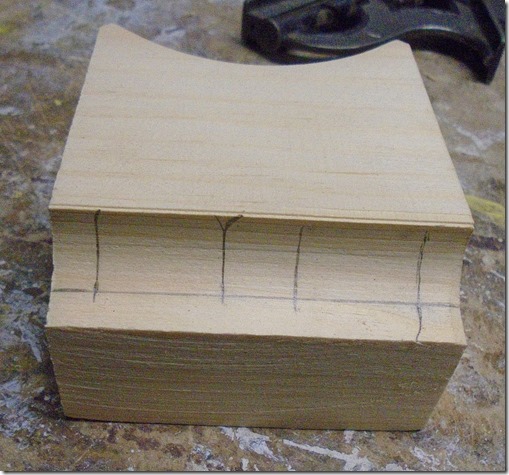

The hardest part of making this was the knurling around the one section. I tried a couple way to do this and the technique I ended up with produced a pretty satisfactory result. To start I used a CAD program to general a series of parallel lines with the spacing I wanted for the knurling.

I used spray adhesive to glue the pattern onto the part.

I also made a block to hold the part while I was cutting the knurling. When making the cuts the tools are going to tend to come off the end of the knurled area, so I wrapped some electrical tape around the part to protect it.

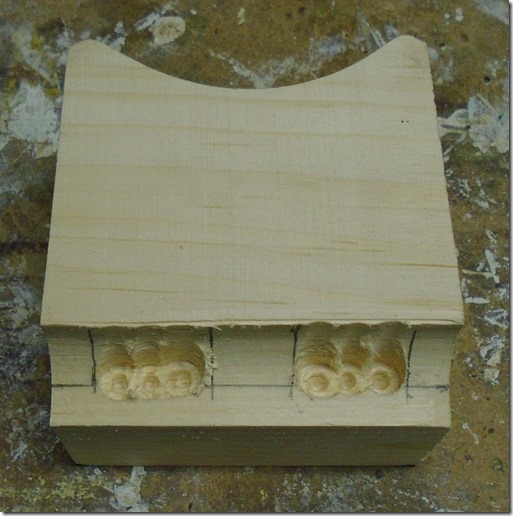

To make the cuts I started with a straight edge and an X-acto knife. Next I used a sharp dental pick to widen each cut. Finally I used to a diamond shape needle file to get the final size and shape of each cut.

With the knurls cut and the rest of the paper pattern cleaned off I put the part back on the lathe to make the groove in the middle of the knurled section.

I my next post I will show how I finished it.