Saturday, December 4, 2021

Rear Logic Display

Sunday, November 21, 2021

Front Logic Displays

The logic displays are composed of three parts, the PCB, a bevel that goes around the LEDs and a clear plastic window.

Saturday, September 11, 2021

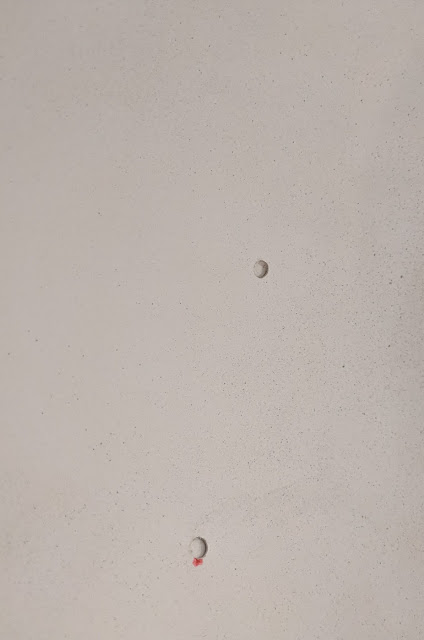

PSI

To mount the Processor Status Indicators (PSI) I used a standard PVC pipe coupling. The PCB fits perfectly in these and they have a ridge in the center that will hold the board in a good spot. Also pictures here is the dome panel that goes in front of the PSI. Not shown is a frosted disk that goes on the front. I cut that disk out of a piece of white plexiglass and glued it to the coupling. The edges will not be seen so the cut doesn't need to be very clean.

Friday, September 3, 2021

Dome Lights Part 1

The first electronic elements I added to R2 were the dome lights. I got an early start on these since I needed to figure out how I was going to mount them in the dome.

There were initially five lighting elements I worked on. On the front are the two rectangular Front Logic Displays and the round Front Processor Status Indicator.

Sunday, July 25, 2021

Painting Part 2

I followed a similar process for the ankle details. These need the tab on the end to be blue and also the recessed rectangle. This required some careful masking.

Saturday, July 17, 2021

Painting

To paint R2, I used off the shelf cans of spray paint.

For the white parts, and as a primer for all the other parts I used Rust-oleum Ultracover Paint+Primer Flat White.

Monday, July 12, 2021

Radar Eye

For the Radar Eye I used a resin casting I purchased online, you can find the details in this post.

The back of the part has four casing points on it that needed to be cut off. I did this with a Dremel and then did some sanding to cleanup that back.

Monday, July 5, 2021

Dome Part 2

Sunday, June 27, 2021

Dome Part 1

My original plan for this build was to make an R5-D4 because I wanted to build as much from scratch as possible and I knew R2's dome would be a challenge. Once I got pretty far along with the build I realized that I had to do an R2 and this would require purchasing some pre-made parts. Some people have experimented with "found" items as a dome, but it's hard to find something that is accurate, especially since R2's dome isn't a perfect sphere, it's actually slightly egg-shaped.

For my dome I purchased the custom made styrene dome from Granite Earth.

https://www.graniteearth.com/ProductDetails.asp?ProductCode=Plastic-Laser-Set

The dome comes in three parts, a laser cut outer layer, an uncut inner layer, and the dome ring which goes between the dome and the body.

The first step in preparing the dome was to cut out the inside of the dome ring. To do this I used a spiral cutting bit in my Dremel and a cutting guide. The cut will never be seen so it doesn't have to be perfect. The bottom edge of the ring also needs to be trimmed. You can see in this picture how it flares out, that pieced needs to be cut off. I did this carefully with an X-Acto knife.

Friday, June 11, 2021

Body Skin Panels Part 3

At the bottom of each side of the body are these cut outs that provide clearance for the battery boxes on the feet when R2 is in 2-leg position

To cover these I attached a piece of styrene, wedging it between the skin and frame on the sides and gluing it to the base on the bottom.

At the top, I cut a half-moon shaped piece of wood to fill the space between the cut out panel and the skin. I also filled the gap between the outer skin and the panel along the sides with hobby putty.

Friday, May 28, 2021

Body Skin Panels Part 2

Some of the skin panels needs to be cut around body details. If you are using standard body detail parts the template may work ok, but since I custom made the front vents and utility arms I traced the parts to be sure I got a tight fit.

The utility arms were really tricky since the cut outs needed to be large enough to allow the arms to swing out. This took a lot of fine tuning even after I attached the body panel.

Sunday, May 23, 2021

Body Skin Panels

Once the two main layers of the skins are installed the next step is the detail panels. When cutting the top layer of the skins I made sure to number all the panels since the cut out pieces can be re-cut to make the detail panels. Here you can see some of the solid detail panels cut smaller to leave that narrow gap around the outside.

Some of the panels need to have the inside cut out with rounded corners are shown here.

To make these I started by cutting the panel to the correct outside dimensions. I then laid out the inside cut.

Next, I made a jig for my drill press that held the pieces in the right position to drill the rounded corners.

Here is the panel with all four corners drilled.

From there I used an X-acto knife and straight edge to make the straight cuts. I then used some sandpaper to clean up the cuts.

These were glued in place using liquid styrene cement and held in place with tape and strap clamps.

Sunday, May 16, 2021

Body Skins Part 3

To attach the inner skins to the wood frame I started by drilling small holes along the top and bottom edge so that I can use nails to hold the skin in place while the glue sets. The outer layer will cover a good part of the inner layer which will hide the nails. To glue the inner layer to the frame I used White Gorilla Glue, https://www.gorillatough.com/product/white-gorilla-glue/

Since I made each layer in two pieces I glues them in place one at a time, further securing them with strap clamps. To glue the outer layer to the inner I used a combination of styrene glues. I first used the Testors gel glue, which has a longer working time then the liquid, being careful not to go to close to the edges with it. I then used the liquid to tack town the edges.

You can see where how I secured the skins with strap clamps and other types of clamps any where I could get them in.

At the seems only a small part of the skin has frame behind it, so I also added some piece of styrene on the back ok the skin to span the seam.