I chose to build an R5-D4 because I wanted a dome that I felt I could build from scratch, but this doesn’t mean that R5’s wasn’t without challenges. The first part of the dome I worked on was the two angled rings that form the neck. I did see a build log for an R5 where the builder created wooden ribs the shape of the head and then used curved strips of styrene for the surface of the angled piece.

I decided to take a different approach, I made the slopped pieces as rings of MDF with the slopes cut into them on a router table. To do this I created another jig, here is what the finished product looks like:

I started with a sloped table with a nail that the part will rotate on. I screwed on the angle pieces so that I could change because the top and bottom rings have a different angle. At the bottom middle of the table is a small slot to provide clearance for the router bit. Next I clamped two strips of wood to the router table to allow the sloped table to slide straight in and out of the bit. Finally I added a stop block so I knew when I was at the finished depth. This technically wasn’t needed since the design of the jig would allow the bit to pass under the part at the end of the bevel.

To use the jig I first cut a disc of MDF using the router table circle jig I have used for other parts. Here you can see the disc mounted to the jig.

Here you can see a close up of how the bit makes the cut.

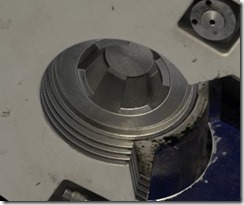

To make the cut I started with the bit lower then the final depth since a lot of material needs to be removed along the outside edge. Since I was cutting MDF I also took some time to setup some good dust collection. I slowly slid the piece into the bit, rotated the disc all he way around, moved it in a little further and repeated the process. Next I raised the bit to it’s final height and repeated the process to get the finished angle. Here is one of the finished rings. To complete it I hand sanded the angle to get it smooth and then I cut the center out using a jig saw since it doesn’t need to be precise.