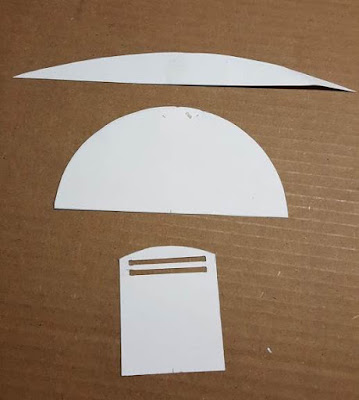

I build the structure of the feet out of wood and eventually finished them with styrene details. In this post I will show the start of the process for building the outer feet. Here are the first three pieces cut out of plywood that form the channel where the foot connects to the leg.

Here you can see how the leg will connect to the foot.

I first drilled a hole in the smaller piece that will receive a bolt to hold the foot to the leg. Next I clamped the small piece to the larger one and drilled the whole through the larger piece. Doing it this way assures that the holes are perfectly lined up.

On the other side of the large piece I added a t-nut that the bolt will thread into.

With the holes drilled I glued up the three pieces and secured them with brad nails.

Next is another plywood piece that will be used to support the styrene on the curved side of the foot.

Here is that place glued in place. The two small holes at the bottom are to secure some old surplus drive units that just happened to have. More on that in another post.

I also created a long hole near the bolt hole that will allow the wires from the motors to be routed into the legs.

Next I cut the ends of the foot out of luan plywood. I didn’t get a good picture of them before I attached them. Before cutting the final shape of these parts I ran the raw piece on the table saw to cut the proper angle on the top and bottom of the part.

The next part is this block added to the back of the foot. The drive motor will go in the front section, and a caster wheel will go in the back. The block is set at just the right height for the wheel I plan to use.

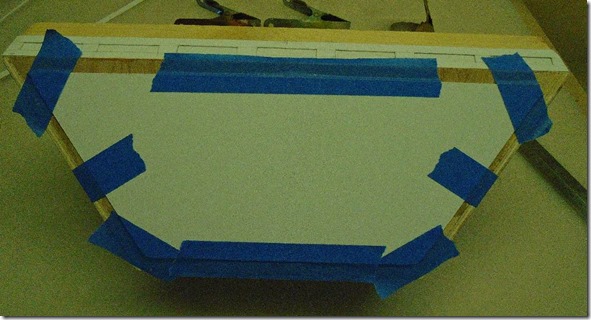

The flat side of the foot is made with another piece of luan, so I first attached some small wood strips along the edge to better hold the side on. Here they are clamped on while the glue dries.

Here is the wood side glued and tacked on.