The part of the shoulder detail is the smaller cylinder. Due to it’s size I decided to make more then one at a time.I started with a dowel of the correct finished diameter and marked of where the cuts need to be made for each part.

I mounted this in the lathe and marked the lines all the way around.

I used the lathe to cut the low areas on the end of each part. The raised area will become knurling.

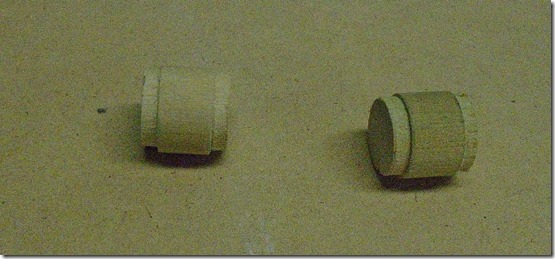

Once the lathe work was done I cut the pieces to their finished length.

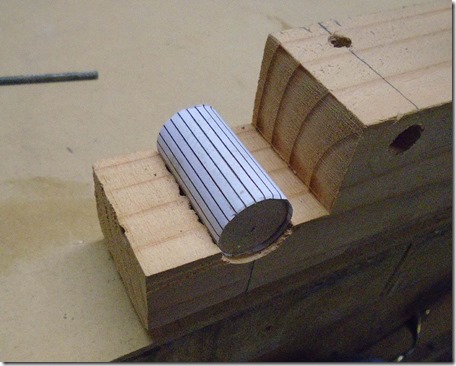

To make the knurling I used the same technique as the large cylinder. I drilled a hole through the part so I could mount it on this jig to make the grooves.

Here is the part with the knurling complete.