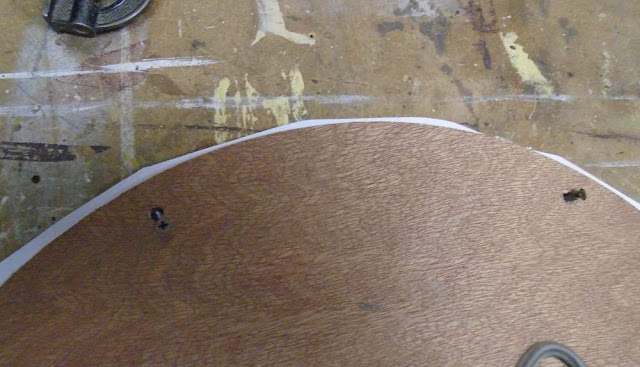

To make the outside cut I used the same router table jig that I used for the outside of the plates and middle ring. Of course these segments don’t have a pivot point so I needed to come up with a way to solve that. My solution was to use a circle I had cut out of a piece of lauan plywood when I was testing out the router table jig. I laid the circle down on top of the segment, carefully aligned the edge with the outside line and then screwed it to the circle.

With the piece attached I flipped the circle over to mount it on the router

table. I made these cuts one at a time, but you could attach more then one

segment at a time to the circle if you wanted to.

I probably could have adapted this jig to cut the inside edge of the segments

but this edge doesn’t need to be as clean as the outside one so I decided to do

the inside edges on a drum sander, just sanding down to the line by eye.

To cut the slots in the ring segments I used the same jig that I used to cut the

slots in the middle ring. I did need to make one change, a large hole drilled in

the plywood back piece , that I could put a clamp through to hold the segment in

place.

No comments:

Post a Comment