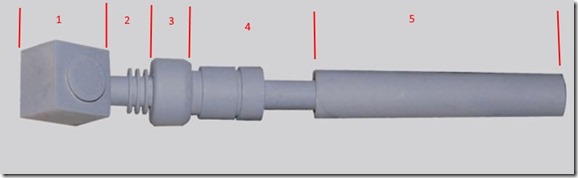

In my last post I showed how I build section 3 and 4 of the leg strut, in this post I will show section 1 and 2.

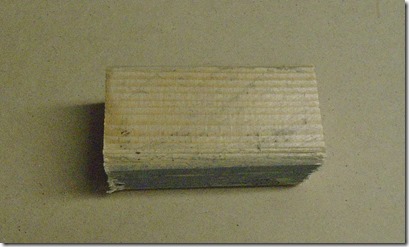

I started out with a piece of 2x2 stock, cut down the width and height on the table saw and finally cut it to length. The circle on the finished piece is to indicate which face will eventually get the disk.

Next I need to drill a hole for the dowel shown in section 2. Here I have marked the location where the hole will go.

Since this has to be drilled and an angle I made up this jig to hold the piece while I drill it. I made the hole with a forstner bit.

Here is the block with the dowel. Not shown here, but I also drilled a small hole in the end of the dowel for a smaller dowel which will attach it to the rest of the assembly.

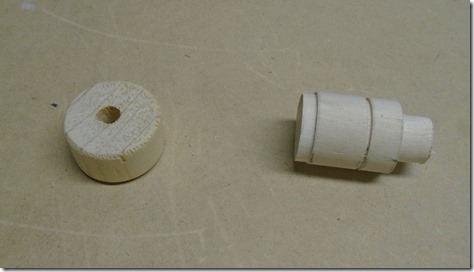

To make section 2 I decided to use a stack of alternating sized washers. I started by making a jig with is simply a small dowel in a piece of scrap. I then put down the first large washer, and then glued on a small one using super glue.,

I then repeated this process with two more large and two more small washers. I put on a stack of washers (not glued) to make up the rest of the height if the dowel and then clamped the whole thing until the glue dried.