In this post I will show how I made the shoulder buttons. Like a lot of these detail parts you can buy resin or aluminum versions of these online, but one of my design goals was to build as much as I can from scratch.

I started by cutting a dowel into pieces the correct thickness. I then used a centering tool (see my last post) to find the center of the dowel. Normally I wouldn’t worry about the angle between the two lines but in this case I also need them to locate the small holes at the edge so I made sure they were 90 degrees to each other. Finally I marked the centers of the edge holes.

I put the dowel in my clamping jig (again see my last post) and drilled the two edge holes.

I also drilled a larger hole which I will need for the raised button in the center.

For the button I used a premade wood plug. These were pretty close to what was needed but the actual buttons are a little more cone shaped and these are a more domed.

To fix this I drilled a small hole in the center of the button and attached it to the end of a dowel with a nail. I then used my small bench belt sander to refine the profile.

Here is it looked like before (on the right) and after (on the left).

Here is the button glued into the base part.

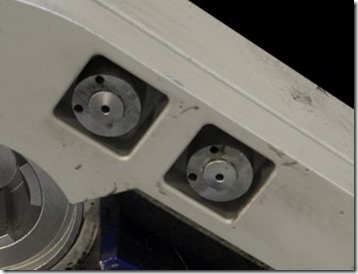

Once the glue was dry I drilled the center hole. Here is the final product with a couple coats of grey primer on it.

No comments:

Post a Comment