The shoulder hub are a little tricky to build. They require quite a few drilling operations and some of them have to be done in a specific order.

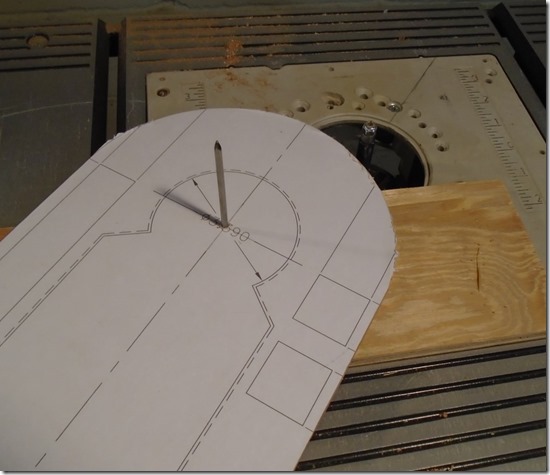

The first step in building the hubs is to cut the disks. These are made from 3/4 plywood and two are needed for each leg. I cut them using my router table and circle jig just like I did with the frame disks.

Once the disks are cut the next thing to do is mark them so you know which ones go on each leg and which is the inside layer (nearest the body) and which is the outside layer (nearest the leg). As I have mentioned before, if you are really accurate with your drill holes, which one goes with which leg isn’t important, but since these operations sometimes aren’t as accurate as we want it’s better to keep things matched up.

Next I worked on mounting the flange to one of the disks. I didn’t want to measure to the outside of the flange since it isn’t machined and is a little inconsistent. Since the threads in the center are machined it was a more accurate place to make measurements. I put a nail in the hole in the disk and used calipers to measure around the nail to be sure it is centered. Once it was centered I marked the position of the holes. I also put a mark on the flange and disc so they could be put back together in the right orientation.

With the holes marked I drilled them with a drill press.

On the other layer I needed to cut out a 3/16” deep area to accommodate the bottom part of the flange. To do this I used a fly cutter in my drill press to make a template. This cut out doesn’t need to be perfect so I made the template slight larger then the diameter of the flange to be sure it would fit properly. I marked the position of the flange on the disc and then screwed the template on. Finally I used a router with a guide collar to cut out the area within the template.

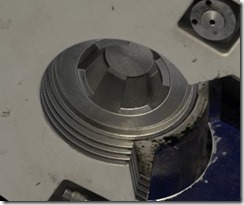

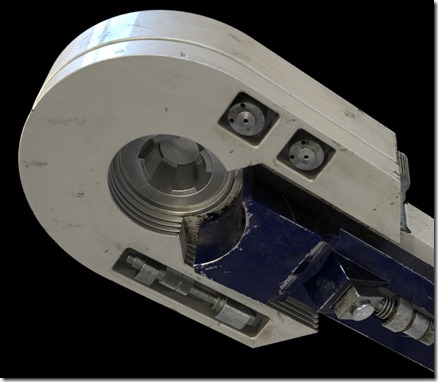

With that cut-out complete I used a 1 5/8” forstner bit to drill a hole through the center of the disc to accommodate the smaller portion of the flange. The area where smaller part of the flange meets the larger part is slightly rounded so you may need to file the inside edge of the hole so it will all fit together properly. There was also some raised lettering on the flange which I had to grind down a bit to make everything fit. Here is the flange sandwiched between the two discs. If done properly the disc should fit tightly together.